Previous article

COB and SMD LEDs - What is the Difference?

Next article

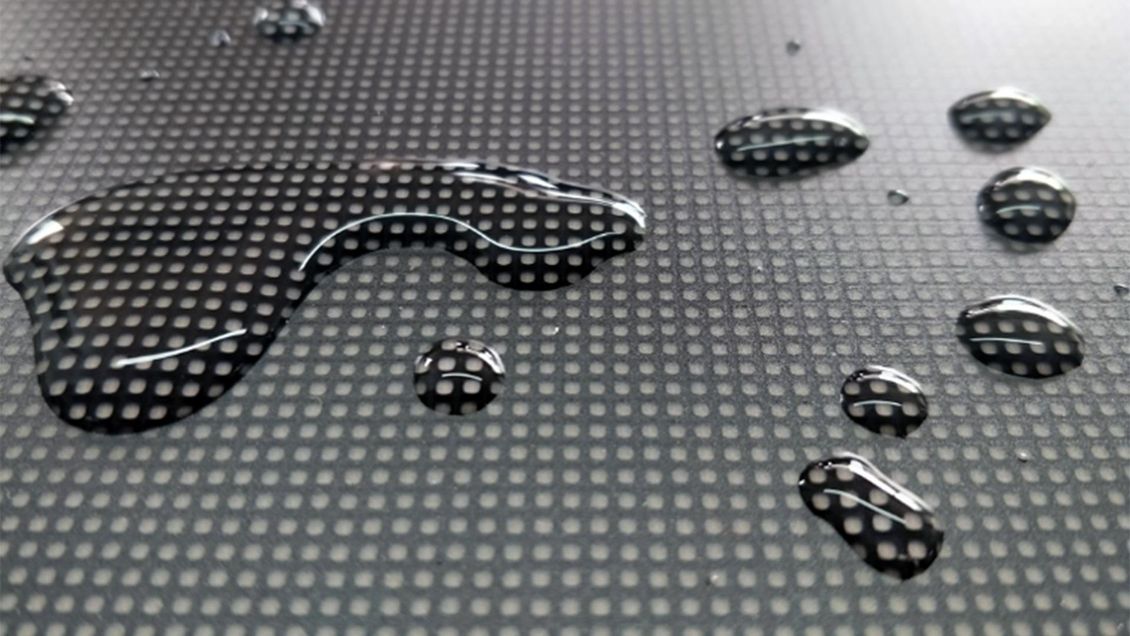

Glue on Board (GOB) is a technology used in the manufacturing of LED displays, particularly in the context of fine-pixel-pitch LED displays. In LED displays, the individual LED chips are mounted on a printed circuit board (PCB), and the traditional method of protecting these LED chips is by using an encapsulation process that involves adding a transparent epoxy layer over them.

However, in the case of GOB technology, instead of using a traditional encapsulation process, a thin layer of epoxy resin is directly applied over the LED chips and other electronic components on the PCB. This process involves "gluing" the components onto the board, hence the term "Glue on Board."

The GOB technology offers several advantages:

While GOB technology has its advantages, it also comes with some challenges. Repairing or replacing individual LED chips can be more complicated compared to traditional encapsulated LED displays. However, advancements in manufacturing and servicing techniques have been addressing these concerns.

Overall, GOB technology has been instrumental in enhancing the performance and visual quality of fine-pixel-pitch LED displays, making them more suitable for various applications, including high-resolution indoor displays and video walls. Ad Art can specify GOB coating as an option with all of its fine pitch LED products for a modest additional cost.

We are committed to providing you with information that will help you make an informed decision. If you need further explanation or support, please feel free to contact us. We are available to assist with questions or issues not covered on our website.

© 2026 Ad Art Electronics Division - All Rights Reserved.