Previous article

What is Glue on Board (GOB) Technology?

Next article

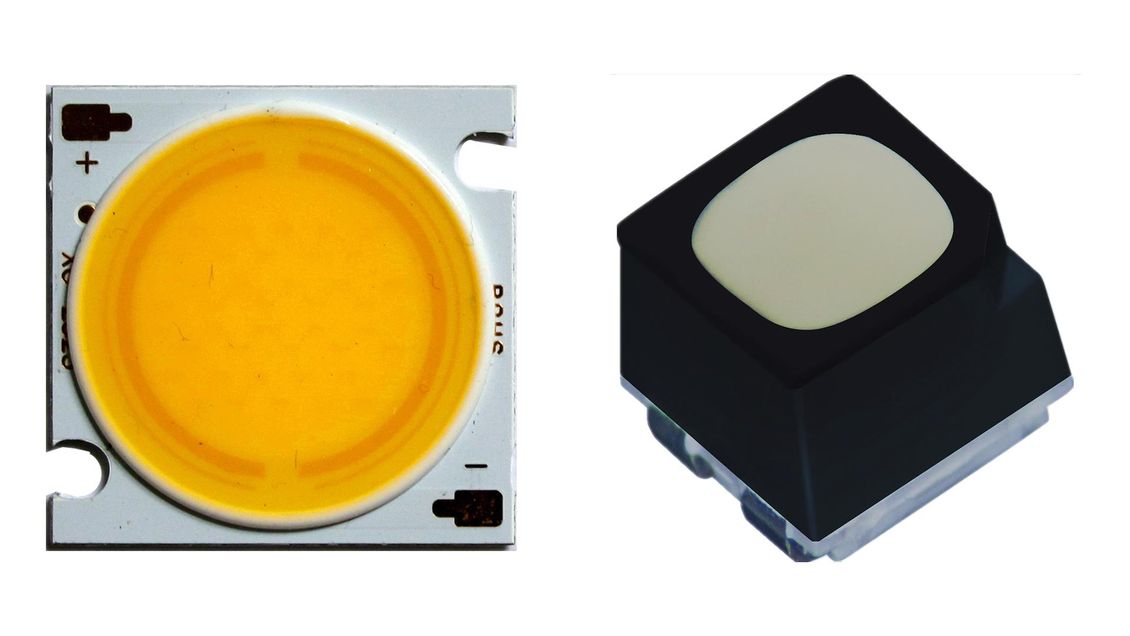

COB (Chip-on-Board) and SMD (Surface Mount Device) are two different packaging technologies used in LED displays. Both technologies serve to package and mount LED chips onto the display module, but they differ in their construction and characteristics. Here's a breakdown of the main differences:

COB: In COB packaging, multiple LED chips are directly mounted on a substrate or PCB (Printed Circuit Board). The LED chips are closely packed together without individual encapsulation, and they are bonded directly to the board's surface using a conductive or adhesive material. This results in a compact and seamless appearance.

SMD: In SMD packaging, each LED chip is housed in a separate package, usually a small plastic or ceramic casing. These individual LED packages are then soldered onto the surface of the PCB, with the electrical connections made via the SMD leads on the bottom of the package.

COB: COB technology allows for high LED chip density since the chips are closely packed without individual casings. This makes COB LED displays more suitable for applications where higher resolution and finer pitch are required.

SMD: SMD LEDs are relatively larger compared to COB LEDs because each chip is housed in its individual package. This leads to a lower LED chip density, making SMD displays more appropriate for applications where resolution requirements are not as demanding.

COB: The direct attachment of LED chips to the PCB in COB packaging results in better thermal performance as the heat generated by the LEDs can be efficiently dissipated through the board. This helps in improving the overall reliability and lifespan of the LED display.

SMD: SMD packages have some thermal resistance due to the encapsulation, which can lead to a slightly higher operating temperature. While modern SMD LED displays incorporate heat sinks and thermal management techniques, COB displays generally have an advantage in terms of heat dissipation.

COB: COB packaging can provide better color consistency across the LED display since the closely packed chips produce a more uniform color output, resulting in fewer color variations.

SMD: SMD LEDs might have slightly more color variation due to the nature of individual LED packages, but advancements in LED manufacturing have significantly improved color consistency in SMD displays as well.

COB: COB packaging can be more cost-effective and less complex to manufacture compared to SMD, especially for high-density LED displays.

SMD: SMD technology is more mature and widely used, making it more readily available and often considered the standard for many LED display applications.

In summary, COB LED displays offer higher density, better heat dissipation, and improved color consistency, but they might be more suitable for specific applications with higher resolution requirements. SMD LED displays are widely used, more cost-effective, and offer good performance for various applications, particularly when extremely high resolution is not the primary concern. The choice between COB and SMD packaging depends on the specific needs and budget of the LED display application. COB technology is provided by Ad Art with select fine pitch models on request.

We are committed to providing you with information that will help you make an informed decision. If you need further explanation or support, please feel free to contact us. We are available to assist with questions or issues not covered on our website.

© 2025 Ad Art Electronics Division - All Rights Reserved.